1 system components

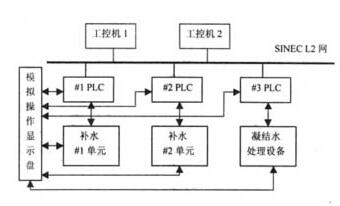

A power plant chemical water treatment system infrastructure equipment has good controllability, the use of PLC and industrial control computer for real-time monitoring and management, the basic composition of the system shown in Figure 1.

Three Siemens Siemens S5-115U programmable controllers are used to control the field of equipment. The program control system is divided into 3 sets, followed by # 1 make-up water treatment unit, # 2 supply water treatment unit, # 3 condensate treatment unit The

Operator station selection of two Advantech 586 IPC, software development platform selection of the United States Intellution FIX5.5 configuration software. FIX5.5 is a complete industrial automation software that can complete functions such as data acquisition and control, alarm, graphic data display. This version runs in WINDOWS or WINDOWSNT environment. The graphical user interface is used. The internal graphics processing is based on Third generation graphics technology.

The data communication system uses the SINEC L2 network, which connects the SIMATIC series programmable controller and the industrial computer into a network. SNEC L2 is a token bus network, the network transmission medium is twisted pair or fiber optic cable. Each node through the bus connector to the bus network, in the system, between the three PLC and between the two industrial computers have achieved data communication.

Figure 1 system structure diagram

The scheme configuration embodies the advantages of the decentralized control system, that is, the control function is decentralized and the operation management is centralized. Decentralized control means that the system is in real-time response and the system is dangerous and decentralized. The operation management is centralized for centralized management and the scheme configuration has redundant characteristics.

2 PLC and its program design

2.1 SIMATIC S5-115U hardware composition and programming summary

Programmable controller SIMATIC S5-115U uses standard modular structure, power supply, CPU, various I / O modules are inserted in a motherboard, and can be based on different I / O points increase the expansion of the motherboard, input , The output module and the memory of the fine classification, making this device has a strong ability to adapt; through the communication processor and local network, can be easily between the PLC and the computer communication.

SIMATIC S5-115U programming language is STEP5, there are three kinds of expression methods, namely the control system flow chart CSF, ladder LAD and statement table STL. The STL which is closest to the machine inside the control program, the function than the previous two Method is much more abundant, so in the system of practical programming applications all the statement table STL.

STEP5 is the biggest feature of the use of structured programming methods, and provide a large number of standard function blocks such as multiplication function block FB242, communication function block FB244, etc., making the programming work greatly simplified, and the programming is clear, easy to read, modify and test , This advantage is particularly evident in the preparation of large complex procedures.

To complete complex tasks, you can divide the entire program into separate blocks. STEP5 has five block types: organization block (OB), block (PB), sequential block (SB), function block (FB), and data Block (DB), where the organization block (OB) is used to manage the user program, forming an interface between the operating system and the control program, and all other types of blocks are called to be executed here. Function blocks (FBs) are used to implement repeated calls or particularly complex program functions that can be provided in the form of standard function blocks or by the user. For example, the standard function block FB242 can achieve 16-bit binary multiplication function, FB244 CPU and communication processor can be achieved between the data transfer, these functions can be used directly call these function blocks.

2.2 SIMATIC S5-115U large program design

Taking the control program of the water supply unit of the system # 1 as an example, the following several statements are mainly organized in the organization block OB1, and the unconditional call of each function block is completed.

JU FB1 (defines PLC1 to two IPC data transmission)

JU FB2 (defines the data that two IPC sends to PLC1)

JU FB231 (complete the basic settings for communication between PLC1 and two industrial computers)

JU FB232 (complete basic settings for communication between PLC1 and PLC2, PLC3)

JU FB4 (for automatic control and bumpless switching)

JU FB3 (pneumatic and electric door control)

JU FB10 (to achieve analog processing functions)

JU FB11 (alarm processing)

FB1, FB2 will be required to communicate the data were written to a data block, such as DB10 corresponding bit, which can be consistent with the variables in the communication processor. In FB231 call the two STEP5 itself provides the standard function block FB244 (send data), FB245 (receive data), and then fill in the communication processor according to some of the necessary parameters such as interface, job number, etc., in order to achieve data communication function. In the FB232 in accordance with the communication processor assigned data bits, the definition of three PLC need to transfer between the data. In the FB4 according to the production process requirements and operating specifications, make full use of other functional blocks and I / O module to send the data to achieve the system of automatic control and bumpless switching function; for a number of similar objects were similar characteristics, were prepared Several representative function blocks FB20, FB30, FB40, for example, FB4 FB20 in a number of times to call the PLC in order to solve a certain program step time and the IPC screen display time to keep the same problem, and FB20 and call the multiplication function Block FB244.FB3 according to FB4 issued by the automatic program step instructions to control the pneumatic doors, electric doors and pumps and other field devices. FB10 is responsible for all the analog processing, in this call the function block FB5.FB11 FB10 converted out of the data, the analog alarm processing, it must pay attention to the analog and PLC internal digital correspondence to To ensure the accuracy of analog display and alarm.

Design of Monitoring and Management Software for Industrial Computer

IPC FIX5 5 is a high-precision modular software system, including a dozen software modules, which mainly introduces the development of the application software used in several software modules The

(1) System Configuration Module (SCU): It mainly completes the network, I / O driver, database name, system startup parameters and initial startup tasks and other configurations. Intellution and third-party vendors have installed more than 300 I / O drivers for PLC and I / O cards, such as SIEMENS, OMRON, MODICON, ABB and other products, and provide I / O driver development kit, For users to develop their own I / O driver.

(2) data scanning, alarm and control module (SAC): it is used to achieve the scene data scanning, signal conditioning, data format and data type conversion, alarm condition identification and remote control output and other functions, SAC will handle the field data Into the real-time database, or remote control output data to the I / O driver, in order to achieve remote control output.

(3) real-time database management module (DATABASE BUILDER): it provides interactive way to build real-time database and online display / modify the function of real-time database, it is the main source of data for the system. Users need to do a lot of work here, the most important thing is to fill in the tag name of the variable, which will field data and database variables in the label one by one in order to call this data in other modules. It is necessary to follow the syntax requirements of FIX software, and then define the tag names according to certain classification criteria so as to improve the efficiency in the future data query and application.

(4) Drawing Module (DRAW): FIX has an intuitive, object-based graphical user interface (GUI) that simplifies the graphical development process. In order to create a picture, you can use the toolbox (TOOL BOX) provided by the DRAW to generate certain objects such as valves, pumps, record tables, etc., and define its dynamic characteristics, that is, the object changes state, size, color, rotation, movement based on field data Such as the opening or closing of the valve, the pump to turn or stop, the work can be completed in a dialog box, mainly in the real-time database variable tags associated with the corresponding object, so that the object state changes with the field data. In order to reduce the graphics development time, Intellution also provides a common device object graphics library, which has a variety of international standard graphics, you can always paste into the user’s screen, while users can draw their own common graphics saved to the graphics library , To facilitate future use.

(5) Display module (VIEW): Its main function is to dynamically display the screen created by the DRAW, you can switch between multiple screens, change the screen shape, enter the data, to achieve monitoring, etc., which is provided to the user’s actual operation screen The

4 system functions

The system has the host computer monitoring function and simulation disk monitoring function, both of which are hot standby mode parallel run. In the host computer screen with the host computer manual, the host computer automatically, the host computer to monitor three kinds of work, the way between the switch is no disturbance.

When the system needs to be monitored by the analog disk, the host computer screen to select the host computer to monitor the work. At this time the system state by the analog disk M / A switch status decision, M / A set manually, you can use the analog disk button on the analog disk for one to one manual operation. When the M / A home automatically, the system can be automated procedures to achieve automatic control of water treatment.

When the system needs to be monitored by the host computer, the PC can be selected on the PC screen manual and PC automatic function. Select the host computer manual, you can in the host computer screen to achieve a one-on-one device in hand operation. Select the host computer automatically, you can in the host computer screen for automatic start and stop control, automatic control program and analog disk automatic control function the same.

5 concluding remarks

In the large and medium-sized production system, the era of single-use programmable controller has passed, and its organic combination of industrial computer and computer network applications, greatly improving the production site automation control level and management level, which is an inevitable trend.