Processing center loading and unloading robot, can replace the manual boring and milling processing unit production line vertical, horizontal, gantry machining center, CNC boring and milling machine in the processing of the workpiece handling, picking, loading and unloading operations such as loading and unloading And process conversion.

Has the following characteristics:

The same time as

High flexibility: as long as the modification of the robot program and grasping fixture, you can quickly put into production.

The same time as

High efficiency: can control the beat, to avoid human factors and reduce work efficiency, machine utilization can be increased by more than 25%.

The same time as

High quality: Robot control system to regulate the entire workpiece processing the whole process, thus avoiding the manual misuse, to ensure the quality of the product. The following is a force for a Changzhou production of automotive air-conditioning connecting rod manufacturers to provide processing center loading and unloading robot solution.

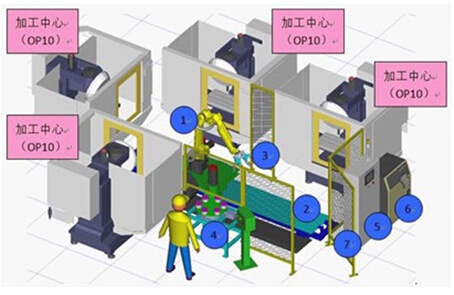

The above figure shows the basic composition of the system diagram: ① M-20iA robot, ② robot walking rail (and robot base), ③ pneumatic double-hand grip, ④ servo rotation up and down conveyor, ⑤ system control cabinet, ⑥ robot control Cabinet, ⑦ safety doors and safety fences.

The same time as

Customers in Jiangsu Changzhou, a production of automotive air-conditioning connecting rod manufacturers, the use of FANUC drilling tapping processing center production. In order to obtain higher quality and shorten the beat time, customers want to be able to use the robot to achieve the automation of the material, so that you can replace the production of a large number of parts, the requirements of high efficiency, artificial simply can not be processed in the timing of the timely processing, The existing manual labor.

The same time as

First, the power of the solution

The same time as

The loading and unloading robot adopts the FANUC robot, and adopts the fast positioning fixture system to realize the high efficiency and high precision pallet automatic processing. Through the configuration of the robot walking guide, increased the scope of the robot loading and unloading operations, you can achieve a robot at the same time for four processing center loading and unloading services to reduce the investment of robots.

Two, four processing center loading and unloading robot integration

1, the robot walking guide: 1 set

2, servo rotary up and down conveyor (including a set of compression handle device): 1 set

3, pneumatic double hand grasping: 1 set

4, the system control cabinet: 1 set

5, safety fence: 1 set

6, personnel access to security door switch: 1 fan