[Introduction]

Mitsubishi Electric FA control technology can strongly support the innovation of semiconductor manufacturing equipment, can shorten the installation and commissioning cycle and reduce software development costs, equipment can be high performance, process stability, equipment, intelligent, greatly reducing the installation area. This example is the Mitsubishi industrial products in a semiconductor cleaning device on the application.

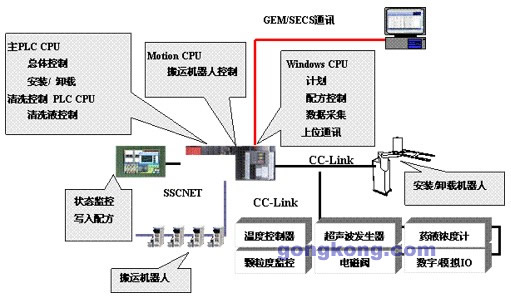

[System map]

[instructions]

In the multi-CPU system integrated with the main control CPU, wash control CPU and Motion CPU and man-machine interface, not only reduce space, reduce costs, but also to control the modular and decentralized.

You can use the Windows CPU to perform GEM / SECS communication and batch download scheduling without the need for a personal computer.

The control of the complex manipulator for slotted wafer conveyance and the position control of the loading / unloading mechanism can be performed with high precision and high accuracy of the Motion CPU.

By using the SSCNET network connecting the Motion CPU and the servo amplifier, the servo motor synchronous and absolute control system can be easily configured and the wiring can be saved.

By using the connection temperature controller and the CC-Link of the remote I / O module connected to the sensor, valve, and switch, the wiring can be greatly reduced and the high-speed I / O response can be maintained.