First, the installation direction and spacing

The back side of MR-JE-40B~MR-JE-100B is equipped with a regenerative resistor. The temperature of the regenerative resistor may rise by 100 °C relative to the ambient temperature. Please take into account the heat dissipation, installation location and use of wires when configuring.

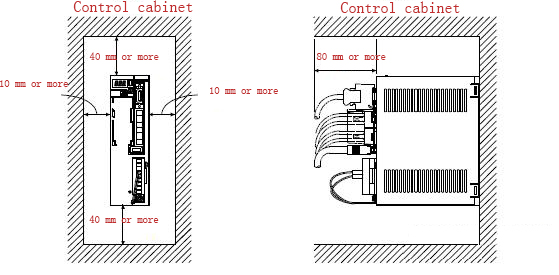

1, the installation interval of the servo amplifier

(1) When installing one set

(2) When installing more than 2 sets

Please reserve enough space on the servo amplifier and in the control cabinet to ensure that the internal temperature of the control cabinet does not exceed the environmental conditions by installing a cooling fan. When mounting the servo amplifier tightly, consider mounting tolerances and maintain a 1 mm gap with the adjacent servo amplifier. In this case, please keep the ambient temperature between 0 °C and 45 °C, or use the effective load factor of 75% or less.

Installation of 2 Mitsubishi servo drives

2, other

When using a heating device such as a regenerative option, take full account of the heat dissipation and avoid affecting the servo amplifier. Install the servo amplifier up and down correctly on the vertical wall.

Second, prevent foreign matter from entering

1. When installing the control cabinet, do not allow cutting debris such as drill bits to enter the servo amplifier.

2. Do not allow oil, water, metal dust, etc. to enter the servo amplifier through the gap of the control cabinet or the cooling fan installed on the upper part.

3. When installing the control cabinet in a place with no harmful gas or dust, please perform forced ventilation (clean air is sent from the outside of the control cabinet to make the internal pressure higher than the external pressure) to prevent harmful gases and dust from entering the control cabinet.

Third, the encoder cable strength

1. Fully consider the cable clamping method. Do not apply bending pressure and cable weight pressure to the connecting part of the cable.

2. When using the servo motor itself, please be careful not to apply pressure to the connection part of the servo motor connector. When fixing the cable, keep the cable (encoder, power supply, brake) and connector connection loose. the amount. Use the optional encoder cable for the bend life. Use a power and brake wiring cable within the bending life range.

3. The outer insulation layer of the cable will be damaged due to the cutting of sharp objects, scratches in contact with the angular edges of the machine, and crushed by people or cars. Therefore, the above situation should be avoided.

4. When the servo motor is installed on a movable machine, the bending radius should be increased as much as possible.

Fourth, the wiring of SSCNETIII cable

The SSCNET III cable uses fiber optics. When the optical fiber is subjected to a large impact, side pressure, stretching, severe bending, rotation, etc., it may cause internal deformation or breakage, making it impossible to transmit light. In particular, the fibers of MR-J3BUS_M and MR-J3BUS_M-A are synthetic resins that dissolve when exposed to fire or high temperatures. Therefore, avoid contact with high temperature parts such as the heat sink or regenerative option of the servo amplifier.

Please read the items in this section carefully and use them with care.

1, the minimum bending radius

Be sure to set the value above the minimum bend radius. Please be careful not to touch the corners of the machine, etc. Please select the SSCNET III cable of the appropriate length under the condition that the size and configuration of the servo amplifier are fully considered and the wiring is not lower than the minimum bending radius. When closing the control cabinet door, please be careful to avoid the SSCNET III cable being pressed against the door and making the bent part of the cable below the minimum bending radius.

2, the use of plastic tape is prohibited

The plastic tape uses a migration plasticizer. Do not touch the MR-J3BUS_M and MRJ3BUS_M-A cables as they may affect the optical characteristics.

3, should pay attention to the migration of plasticizer additives

In general, soft polyvinyl chloride (PVC), polyethylene (PE) and fluororesin contain non-migratory plasticizers that do not affect the optical properties of SSCNET III cables. However, some wire insulators, cable ties, etc. containing a migration plasticizer (phthalate type) may affect the MR-J3BUS_M and MR-J3BUS_M-A cables (made of plastic).

In addition, the MR-J3BUS_M-B cable (made of quartz glass) is not affected by the plasticizer.

In addition, chemical substances may affect the optical properties, so it is necessary to confirm the influence in the use environment beforehand.

4, the fixed line

In order to avoid the CN1A and CN1B connectors of the servo amplifier from bearing the self-weight of the SSCNET III cable, the cable part close to the connector should be fixed with the wire material as much as possible. To prevent less than the minimum bend radius, the fiber optic cable section should maintain a slack margin and do not distort the location. When the cable is bundled, use a cushioning material such as a sponge or rubber that does not contain a migration plasticizer.

When using a bonding tape for the wire harness, it is recommended to use a flame retardant acetate adhesive tape 570F (Tejioka Manufacturing Co., Ltd.).